-

11b Adeola Odeku Street

Victoria Island, Lagos, Nigeria.

-

Call Us On

+234 8118193592

-

Mail Us @

info@wabecopetroleum.com

Product Stored

Premium Motor Spirit (PMS) Automotive Gas Oil (AGO) Dual Purpose Kerosene (DPK)

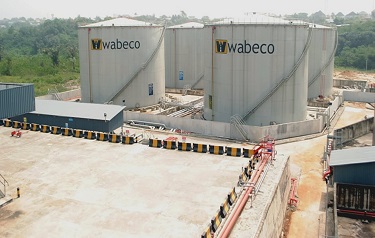

Storage

There are 4 nos Cone Roof, Steel Vertical Storage Tanks (VSTs)designed to API 650, each of Diameter 25m, Height 17.5m and Nominal Volume 8.6 ML,. In addition to the normal tank-body fittings and fixtures, the VSTs are equipped with the following

- Automatic gauging using radar type level transmitters,and inventory system

- Product high-level and low-level indicators and alarms.

- Water drenching system for tank cooling.

- Foam deployment system for fire fighting.

- Cathodic protection to combat corrosion.

Health, Safety and Environment

The depot is equipped with the following safety features:

Electronic flame detector cells installed at calculated points for fire detection. The activation of any of the cells would initiate the following actions:

- Set off the audible alarm system.

- Close all emergency product supply valves

- Shut down all product pumps

- Start fire-water diesel-driven pumps

- Open the valves on the fire system in the appropriate areas

Download pdf Information Sheet Click Here

Depot Piping

The depot piping consists of various Sizes of Schedule 40 MS pipelines. Above-ground pipelines are externally painted and buried pipelines are externally wrapped. The pipeworks for Dual Purpose Kerosene(DPK) are internally lined for possible Aviation Turbine Kerosene (ATK) service.

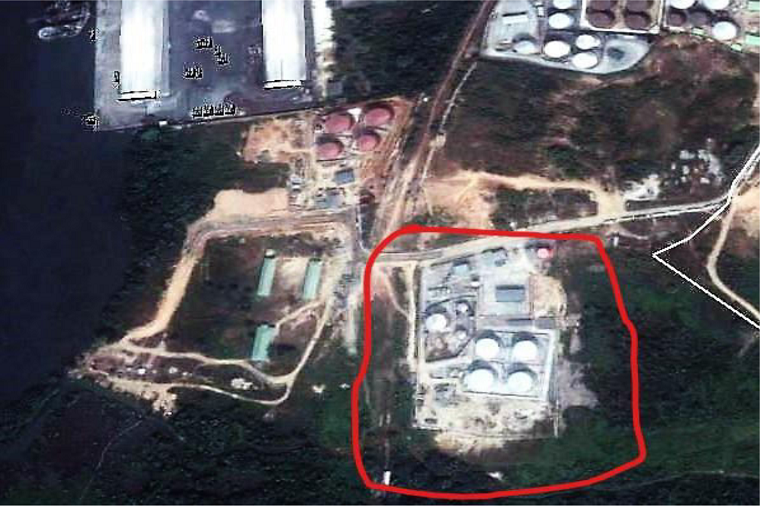

Cargo Line

The depot is fed by a number of pig-able 1,800m, Diameter 10” pipelineslaid from the ECOMARINE portion of the NPA Jetty, Calabar to the depot. The pipelines are all protected against corrosion by wrapping or painting, as appropriate and cathodic protection.

Product Loading

The depot has one loading gantry of 3 islands/6 loading bays for the top-loading of products into Bulk Road Vehicles (BRVs). Product metering is by pre-set automatic metering equipment which is linked to the depot automation system. The loading bays are segregated by product.

Product Pumps

There are 7pumpsproduct pumps which are driven by flame/explosion proof electric motors:

• 6 nos of 140 m3/hr –h71mpumps for BRV loading.

• 1 no of 450 m3/hr –h77mpump for back-loading product to vessels at the jetty.

BRV or Road Tanker Loading Rate

The depot can load up to 114 BRVs or Road Tankers in an 8-hour working day.